Compact Laminate Facade Coating Systems

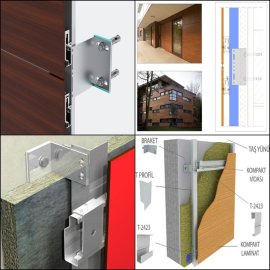

Kompakt Laminat Cephe Kaplama, alüminyum profillerden yapılan, binanın dışına estetik bir görünüm kazandıran kompakt laminat plakaların güvenli bir şekilde monte edilmesinden oluşan cephe sistemidir. Diğer cephe sistemlerine göre birçok artısı olan kompakt laminant cephe kaplamalarının en büyük artısı binanın nefes almasını sağlamasıdır. Bunun için havalandırmalı laminat alt konstrüksiyon kullanılmalıdır.

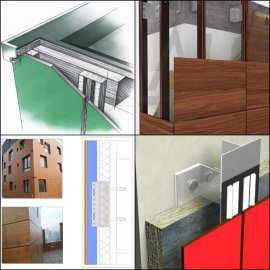

Kompakt Laminat Cephe Kaplama Sistemleri, ahşap ve ahşap türevi ürünlerde, zengin renk seçenekleri, fiziksel ve mekanik özellikleri ile mimari yapılara kazandırdığı estetik görünüm sayesinde dış cephe kaplamalarında Türkiye ve dünya pazarında, aranan bir ürün haline gelmiştir. Dış cephe kompakt laminat panelleri, konut, iş yeri ve alışveriş merkezleri, bankalar, kamu kurum ve kuruluşları, hastaneler gibi her türlü dış cephe uygulamalarında kullanılmaktadır. Kompakt Laminant Cephe Kaplama Sistemi Agraflı, Perçinli ve Yapıştırmalı olarak üç farklı şekilde uygulanır.

Compact Laminate Facade Coating Systems Catalog

Types of Compact Laminate Facade Coatings

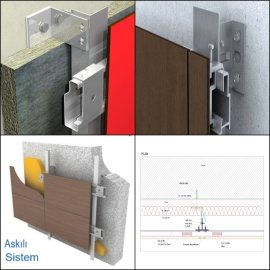

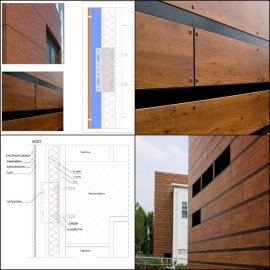

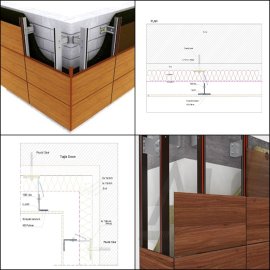

1. Mechanical Attachment System

This system is applied by hanging 8 mm or 10 mm compact laminate panels on aluminum vertical and horizontal carriers with aluminum attachment apparatus screwed to their back sides. This method is especially widely used for coating the facades of multistorey buildings.

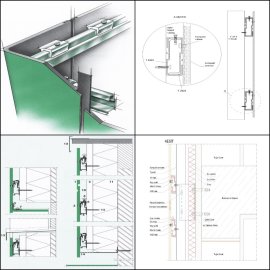

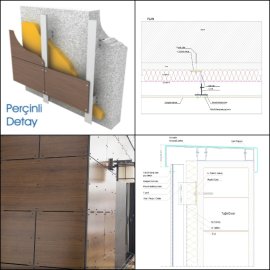

2. Mechanical Riveted System

This system is applied by fixing 6 mm or 8 mm compact laminate panels on aluminum vertical carriers with rivets in the color of the selected panels in accordance with the technique. The system is preferred for facade coating of buildings with large openings due to its mechanical, fast application, robust structure and its being affordable.

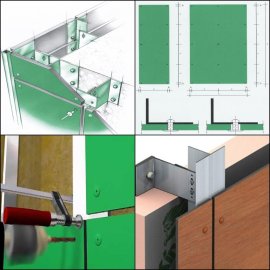

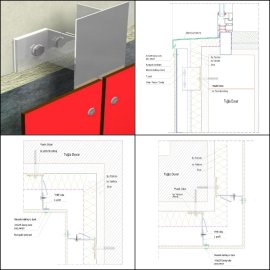

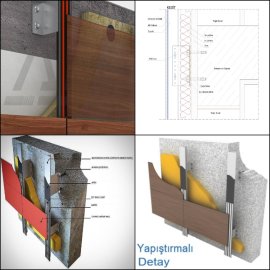

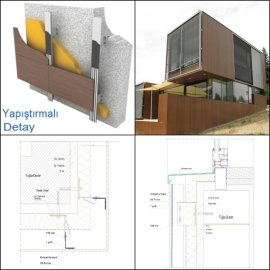

3. Mechanical Adhesive System

This system is applied by using 6 mm or 8 mm compact laminate panels on aluminum vertical carriers using panel adhesive systems produced for exterior facade conditions. The system is the most widely preferred application method with its convenient, fast-applicable technique for the implementation of creative designs. Thanks to its high technology, it is resistant to impacts, fire, water and moisture. In addition to these features, it does not rot, does not harbor bacteria and can be easily cleaned.